Growing from collaborations with global companies and understanding the need for quality products, we have come a long way in creating opportunities beyond boundaries.

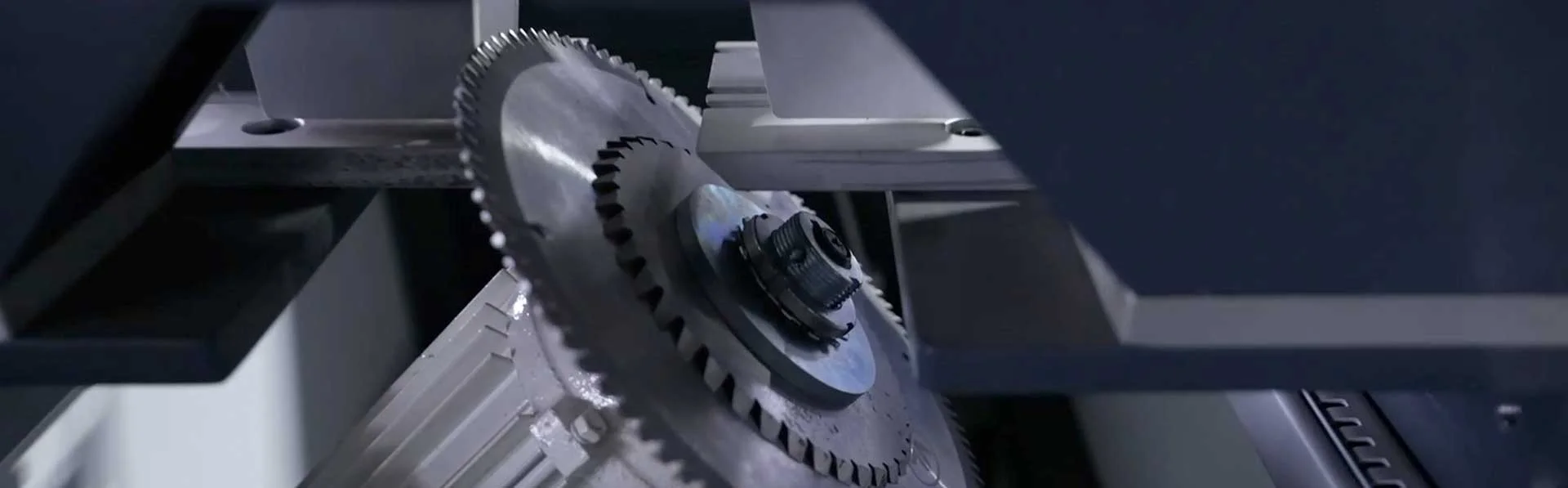

Our high-end precision machines, laser cutting machines, and immaculate tools function in our vast 2-acre production area.

Our ability to envision the emerging trends and stay adept with newer technologies has helped us enhance your homes and offices’ style quotient.

SIMTA uses high-end laser cutting machines for precise engineering. Cutting and engraving through laser is a contactless procedure that results in cutting-edge products giving the freedom for making complex structures. In addition, the machine adheres to European standards for best-in-class tooling.

SIMTA uses a high-speed, streamlined and high-precision CNC sheet metal press brake for precise tooling. The machinery follows standard European style tooling for the highest quality, and with CNC-controlled automatic crowning, precise tooling is assured.

We have an in-house lab facility equipped with testing equipment from Europe and Japan to facilitate the best machinery for UPVC doors and windows. Quality and customer satisfaction is our utmost priority, and we have a state-of-the-art infrastructure to provide the same. Our R&D department has some best brains with 3D printers and a prototype testing facility that ensures every product goes through an intricate testing procedure for giving the best-assured quality.

We make well-designed dies, calibrators and tank plates with high-quality tool steel. We have highly competent and certified tooling specialists for world-class tool maintenance for our tool handling and practices. We also have in-house capability of die design which makes us a leading UPVC machinery manufacturer.