An angle is formed by the fusion welding process in high precision Lock Hole Routing is a process where slots are created in fabrications for fixing locks and handles. This tool has two parts: the upper one for creating the template for drilling and the lower one for creating the holes. Our USP is the use of the unique self-centring device, a high precision device used for marking slots to prevent any false marking leading to faulty installations.

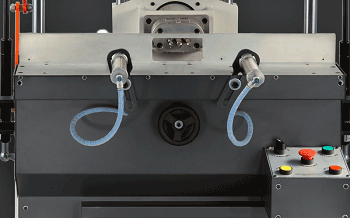

Triple drilling is the process used to create the slots using a double tool where the bottom tool has three spindles and the top tool has the template for creating the slots or holes.

Lock Hole Routing system is used to create the slots to complete the frame functionally. Lock Slots and handle slots are created using this technology by us at SIMTA.

Cuts down the manual intervention for marking the points to make slots as the marking is done by the machine itself by the self-centring process.

| Routing Spindle Rotation: | 12000 rpm |

| Drilling Spindle Rotation: | 910 rpm |

| Routing Length: | 600 mm |

| Stroke: | 100 mm |

| Max Profile Dimensions: | 110mm x 110mm |

| Power Output of Motor: | 2.0 kW |

| Pneumatic Cylinders & Its Accessories: | SMC, Japan. |

| Electrical Components: | Siemens & Schneider Components |

380-415v, 3 ph, 50-60 Hz.

Up to 6 - Bar

250 kg

H 1500 mm

L 2250 mm

W 1100 mm